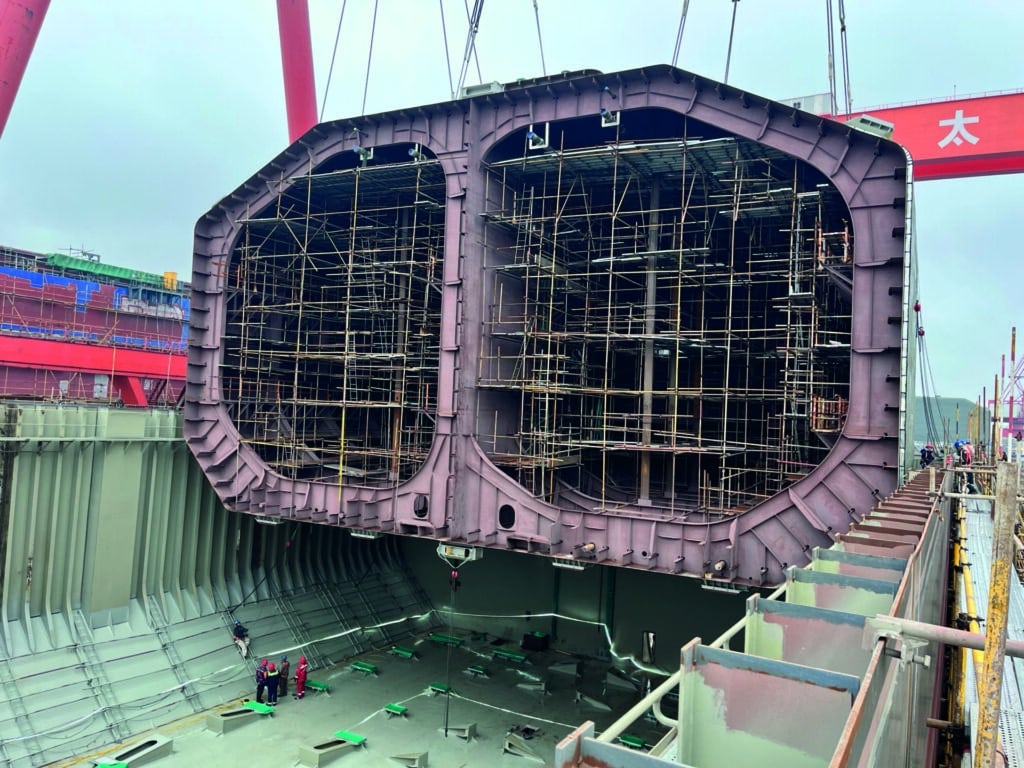

EXMAR’s China supervision team, located in Qidong, China at CIMC Sinopacific Offshore & Engineering (SOE) Shipyard, is busy with the construction supervision of the next four 41k LPG dual fuel carriers for our fleet. All four ships are currently under construction, with expected delivery of the first vessel near the end of this year.

TEAMWORK

The site team in Qidong is a mix of new supervisors as well as those who have worked extensively with EXMAR before, a mix of those bringing over 20 years of experience in the shipbuilding industry to the shipyard and a new young workforce helping to turn this project into a success.

FINDING NEW WAYS

This project is a bit different from our usual newbuilding projects, since we bought the ships under construction from Avance Gas. “With plan approval completed and keel laying of the first ship done, the EXMAR site team had to navigate which decisions had been made and what was still possible to change and bring to EXMAR standards”, our project manager, shares his take on the project.

It is also the first time that CIMC-SOE is building a midsize LPG carrier with Type-A cargo tanks. “That means the shipyard is completely new to this kind of vessel. Our team on site brings EXMAR’s extensive experience, ensuring that the ship is built to the highest possible quality and safety standards.”

FINISH LINE ON THE HORIZON

It was a hard first few months, with plenty of discussions with the shipyard to ensure that the launch of the first vessel would meet EXMAR’s expectations. Challenges arose in all disciplines, ranging from the construction and installation of the cargo tanks to the painting of the hull and the shaft alignment. The fact that CIMC-SOE is a relatively small shipyard brings some obstacles like cultural differences, but have been easily overcome by a motivated team.

“A clear positive, however, is that everyone on our team is willing to improve and our experienced supervisors know how to navigate challenges as they have always done so. The site office gets daily visits from designers, quality managers and production managers who listen to our ideas and improvements and try to implement them in the construction as much as possible. This close cooperation will be key to ensuring that this project becomes a success. If all goes well, we can expect the first vessel delivery by the end of this year.”